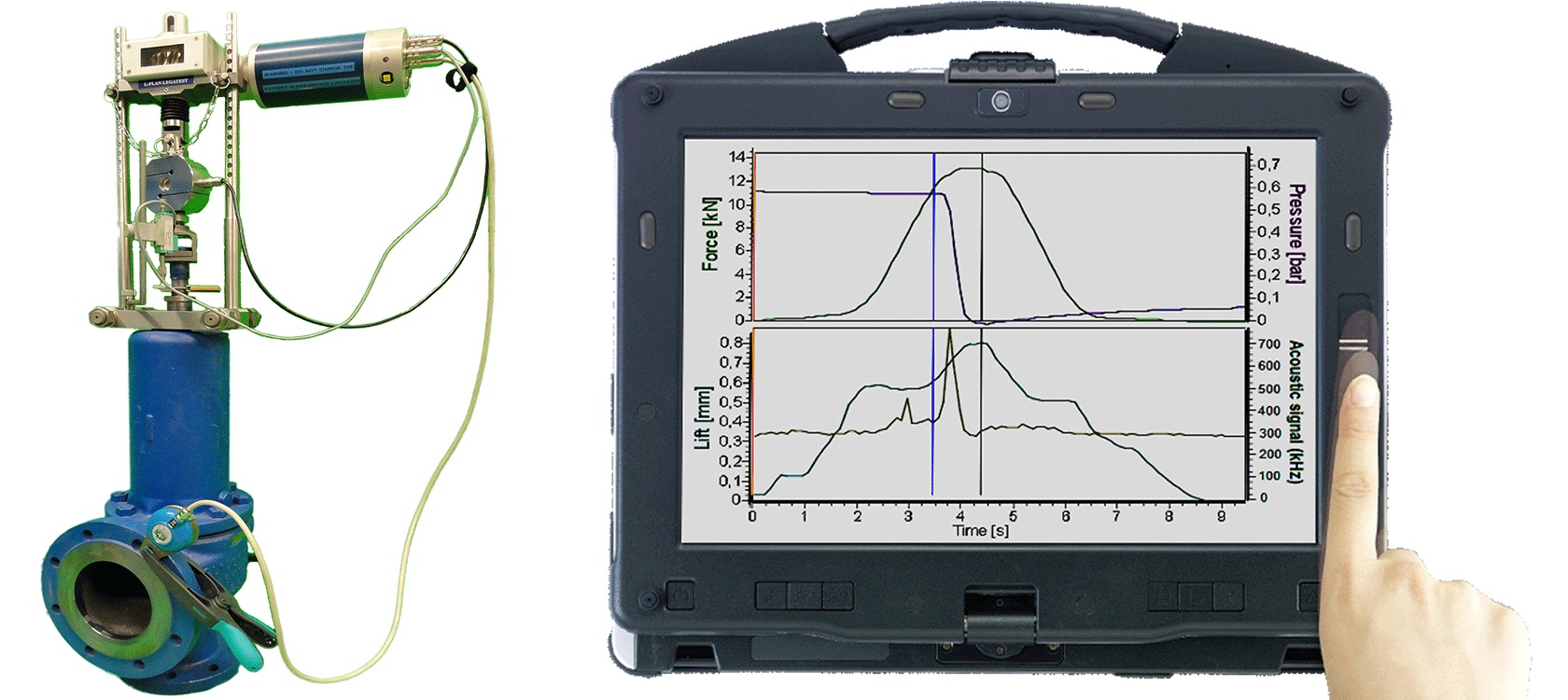

L-plan patented device

On Line, On Site, Under Operation Safety Relief Valves Testing / Inspection

lplan

Why on-line (on-site, in-situ, during operation…) safety relief valves testing?

- Less shut downs – less production loss!

- No system discharges – no fuel costs!

- We improve the environmental conditions!

- No stress on pressure equipment joints, pipelines…

- No removing safety valves from the system – We save time and money.

Read more: Why on-line (on site, insitu, during operation…) safety valves testing?

Safety valves functions can be monitored and tested with greater accuracy, than conventional PSV testing on the test bench. How???

- Because, Legatest is a special high accuracy on-line testing device.

- By keeping the requirements of the standard EN ISO 4126-1:2013, chapter 7.2.3: »The uncertainty of pressure measurement shall be within +- 0,5 % in the temperature range between -15°C up to 60°C.«. How is it possible?

- With an innovative approach to some limitation overcome.

- With an innovative approach in the introduction of testing methods during operation.

- With a very good knowledge of the operation of safety valves and process pressure equipment.

With a daily using the Legatest device for on-line safety valve testing like Conformity Assessment – Inspection body since 1996!

Read the details about on site safety relief valves testing accuracy…

Why is electric motor drive better then hydraulic?

The safety valve is not closed after the test. We don’t have enough difference between system working pressure and safety valve opening point! How to overcome this unpleasant situation?

Opening pressure is sometimes hard to determine. Why?

How motor drive influences on safety of work?

The valves are sometimes installed in very inaccessible areas. Management of the test should be done so by vast distances.

How the on-line testing with Legatest could be extremely effective?

How is the power supply?

Legatest device is power autonomous. With full charged batteries 200 normal on-line safety valves tests can be implemented (50 tests up to 50 kN).

In some environments it is difficult to access or prohibited because of potentially explosive areas…

Legatest device can be use in potentially explosive atmospheres according to directive 94/9/EC.

EC Type Examination Certificate Nr: SIQ 11 ATEX 134 X for Ex cones: II 2 G Ex d(ib) ib IIC T4 Gb as same as approved: Certificate of Conformity.

Read the unswers on your questions…

How is the Legatest device so safe, versatile and easy for use?

- We are daily using the equipment which was developed and produced in L-plan like Conformity Assessment – Inspection Body, process pressure equipment area.

- Due to the hardware independent monitoring.

- Several safety protections are applied

- Because of motor consumption monitoring and factory calibration with force, some advantages have been made.

- Testing phase can be automated.

Read more about safe and easy use of the Legatest device…

Legatest device applicability of using in the execution for other on-line tests

Regarding on innovative solutions and high accuracy technology, on-line safety valve testing device Legatest can be performed also for on-line, under operating testing of other valves types:

- Pilot assisted safety r. valves

- Pressure – Vacuum relief valves

- Pneumatic control units assisted safety r. valves

The Legatest device can be used for on site testing of small seat diameter valves, < DN20 (1/2”…)

Trainig for on-line safety valves testing and for Legatest device use we always suggest…